.jpeg)

What is PapRap?

Eco-Friendly Wrapping Redefined, PapRap stands for Paper wRap. It is an innovative, cost effective, eco-friendly and versatile wrapping material that’s set to replace the plastic bubble wrap . It is done by upcycling old carton boxes.

The New Kid in the Bubblewrap Market

Why Recycle When You Can Upcycle?

The Most Sustainable, Economical Packing Option

Why Choose Paprap?

Compostable

Since the raw material is unbleached kraft paper that can get composted along with any paper in any landfill - unlike plastic bubble wraps that may lead to microplastic.

Sustainable

Since it is made by upcycling old/wasted corrugated boxes that would have otherwise gone through an energy-heavy journey of transportation, pulping, paper making, corrugation, and box making.

Reusable

Since there are no bubbles to burst, it can be used more than once, making it a cost-effective and sustainable choice for packaging.

Repurposed

The main ingredient is sheets from old corrugated boxes, giving new life to discarded materials and reducing landfill waste.

Recyclable

At end of life, the whole product can be sent to paper mill for making pulp and paper.

Versatile

We can make PapRap from a combination of paper/pellet types that suit the budget, ensuring flexibility without compromising on sustainability.

Zero-Waste

Any kind of waste from the process is sent for pulping, ensuring a zero-waste approach and contributing to a circular economy.

Planet Preferred Packaging

Step 1

Corrugated sheets from old carton boxes are cut into small pellets Old carton boxes image – pile of pellets

Step 2

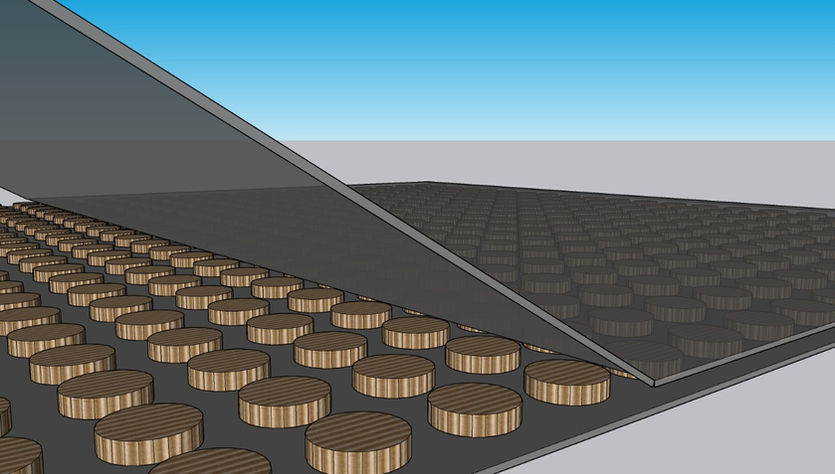

These pellets are placed between two sheets of paper with gaps between them by our machines Image of paprap with inside shown.The pellets provide cushioning and impact protection. The space between the pellets make the product flexible and wrappable Relevant images – 2 nos Voila. We have PapRap, a great substitute for the plastic bubble wrap.

Step 3

Use it for wrapping products. With a potential market size of $ 50 billion globally, with the whole world waking up to sustainability in packing, with the products scoring high on cost advantage and usage, the future is indeed looking green.

Paper Customization

The two layers of paper can be customized with a choice of white paper, kraft paper, or duplex paper for the outer layer. Offset printing (single/multi-color) is available if required. The inner layer can be made from a suitable paper, including newspaper to reduce costs. Different BFs/strengths and thicknesses starting from 30 GSM can be chosen for various applications.

Pellet Variations

The corrugated pellets inside can be customized in different sizes and shapes. Based on application needs, the product can have 3, 5, or 7 plies to enhance cushioning and durability.

Water & Tear Resistant

The outer layer can be coated with a proprietary cellulose to make it moisture-resistant. For added durability, a layer of threads can be introduced to make it tear-resistant.

Multi-Layer Option

Share information on a project here to attract new clients. Provide a brief summary to help visitors understand the context and background of the work.